1. Description

DIHORSE Automatic fiber laser welding machine comes standard with a Raycus Laser source, its service life reaches 100,000h; Additionally, uniform power output and homogeneous intensity distribution guarantee excellent seam qualities and high process stability. The machine can be customized with automatic fixtures, or integrated into assembly lines for mass production.

The 500 W automatic fiber laser welder can be upgraded with larger power options to achieve welding of thicker workpieces.

2. Features

- Real-time processing display and waveform control functions to achieve ideal welding conditions;

- Four-axis control system, easy to program, debug and maintain.

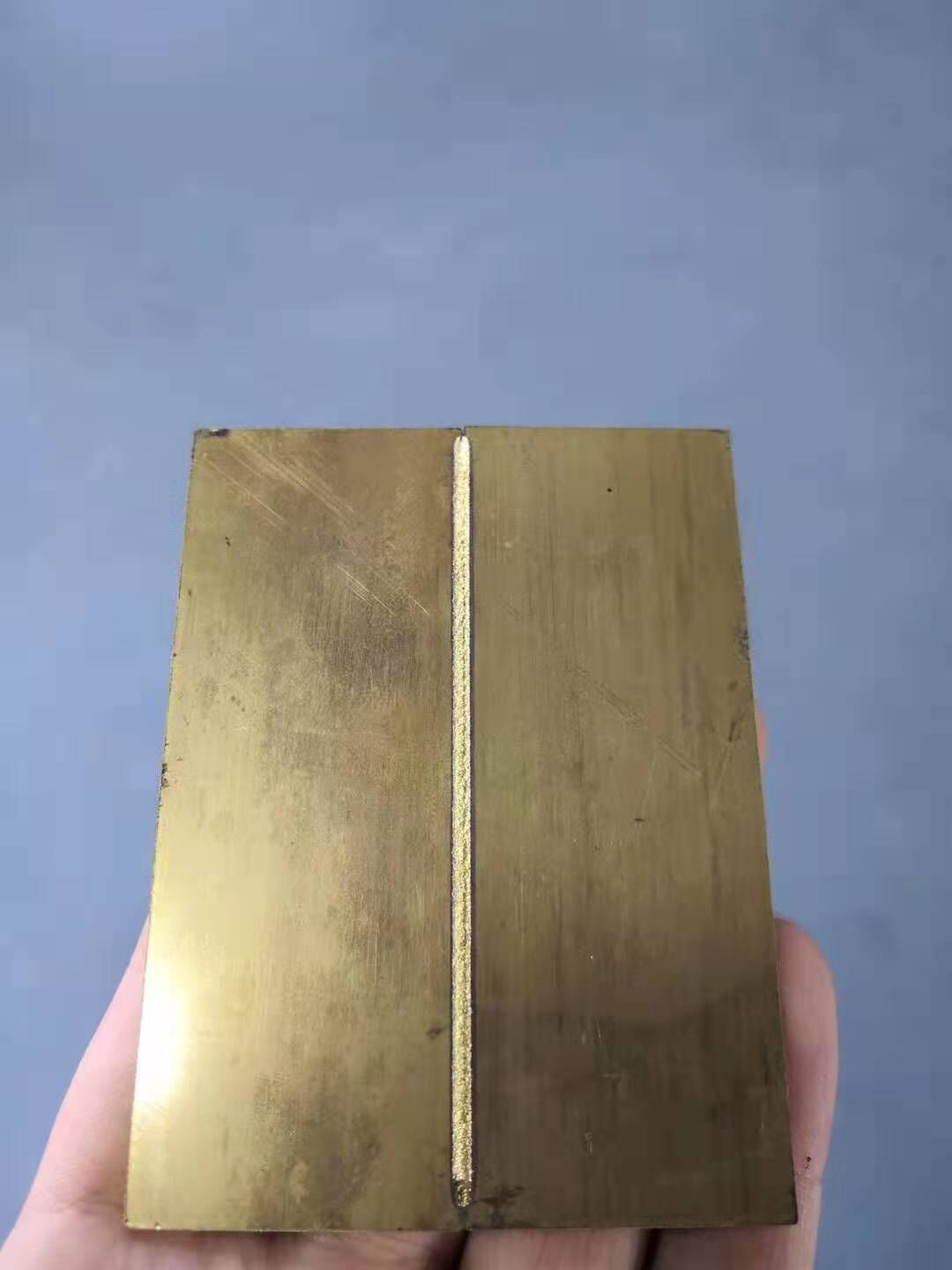

- Smooth and high strength welding seams that do not need any post-processing;

- Fast speed, more than 5 times the speed of the traditional fiber transmission laser welding machine;

- Large depth, small taper, high precision, solid welds fully meet the needs of users in different industries;

- Time splitting or energy splitting, suitable for different processing applications, multi-station processing applications;

- Optional robot, boom, CCD camera monitoring system for special welding, precision alignment and real-time monitoring of welding.

3. Parameters

1000W Automatic laser welding machine | |

Model | DH-CW1000 |

Laser source | Raycus |

Laser power | 1000W (1500W/2000W/3000W optional) |

Output Power Tunability (%) | 10-100% |

Laser head | Automatic |

Laser wavelength | 1085nm |

Fiber diameter | 100μm |

Frequency of pulse | 50~20khz |

Way of working | Continuous |

Electric current | 10-32A |

Spot Size | Φ0.2-1.8mm |

Welding depth | 0.8-1mm |

Impulse Width | <10MS |

Cooling system | Water cooling |

Water chiller | S&A 1000w |

Total power | 6KW |

Ambient Temperature | 10℃~40℃ |

Relative Humidity | ≤70% |

Power supply | AC 220V, 50Hz |

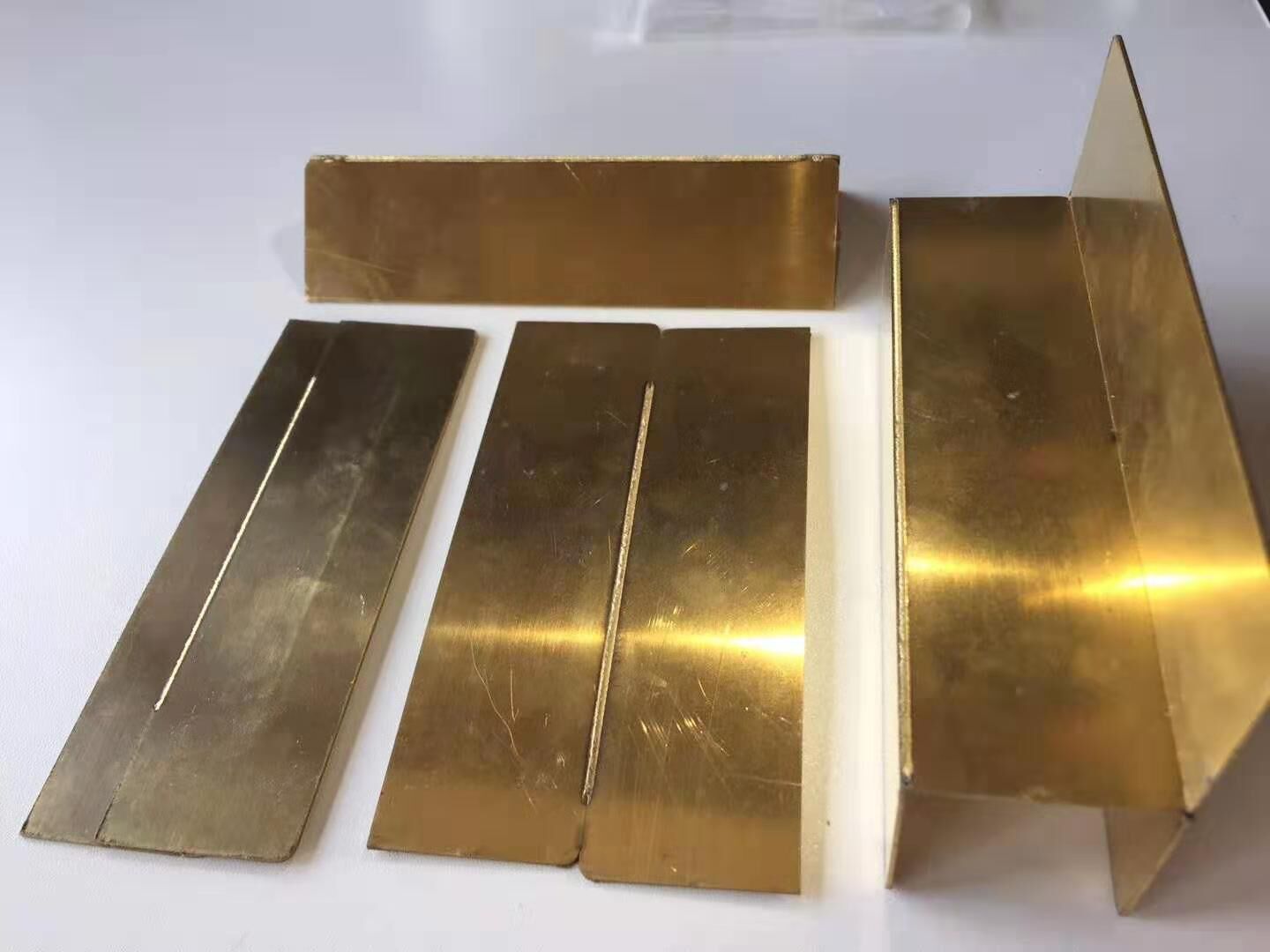

Apply materials | SS, CS, Aluminum, Brass |

Max thickness 1 | 3mm SS, 3mm CS |

Max thickness 2 | 0.5mm Aluminum and Brass |

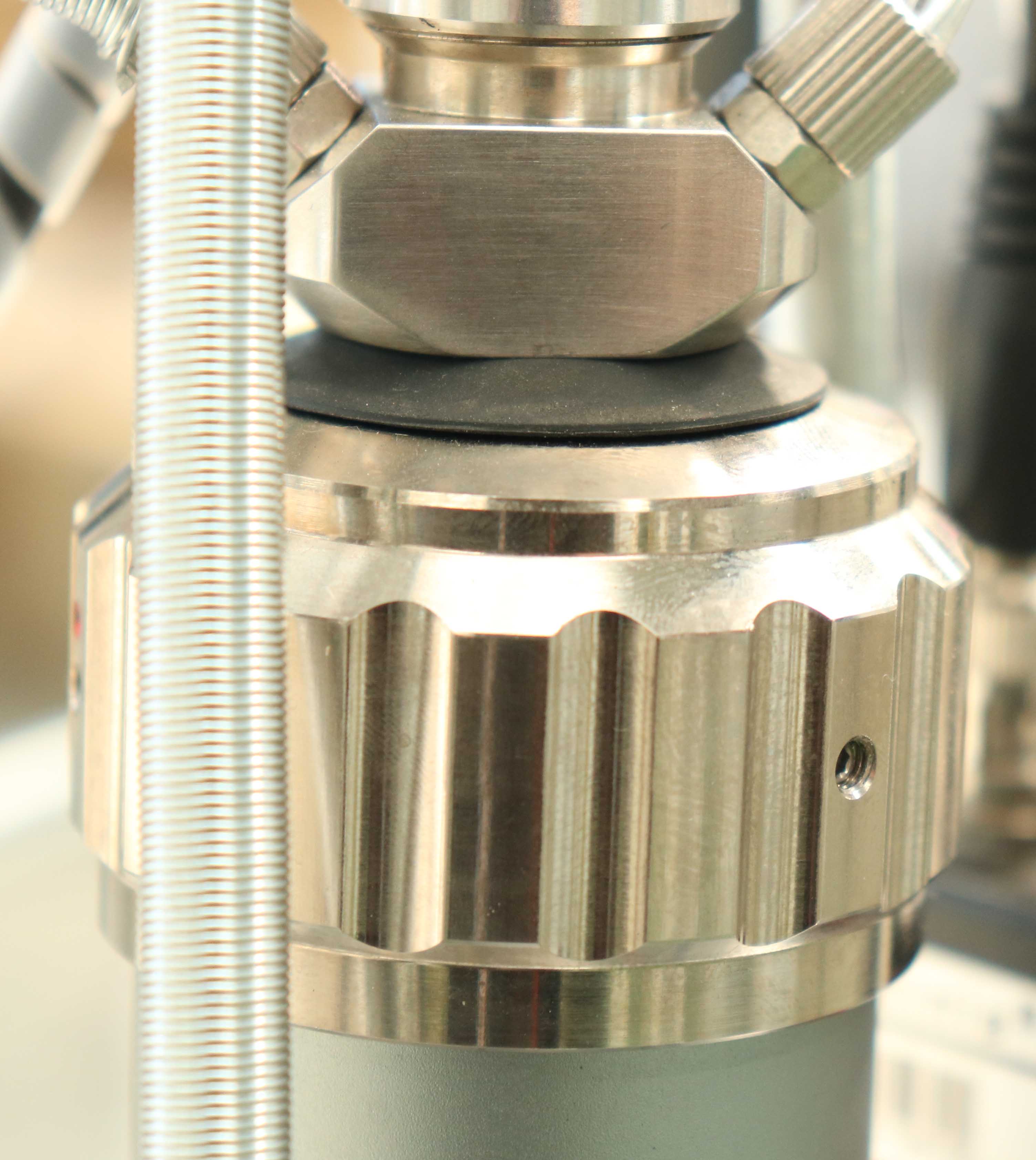

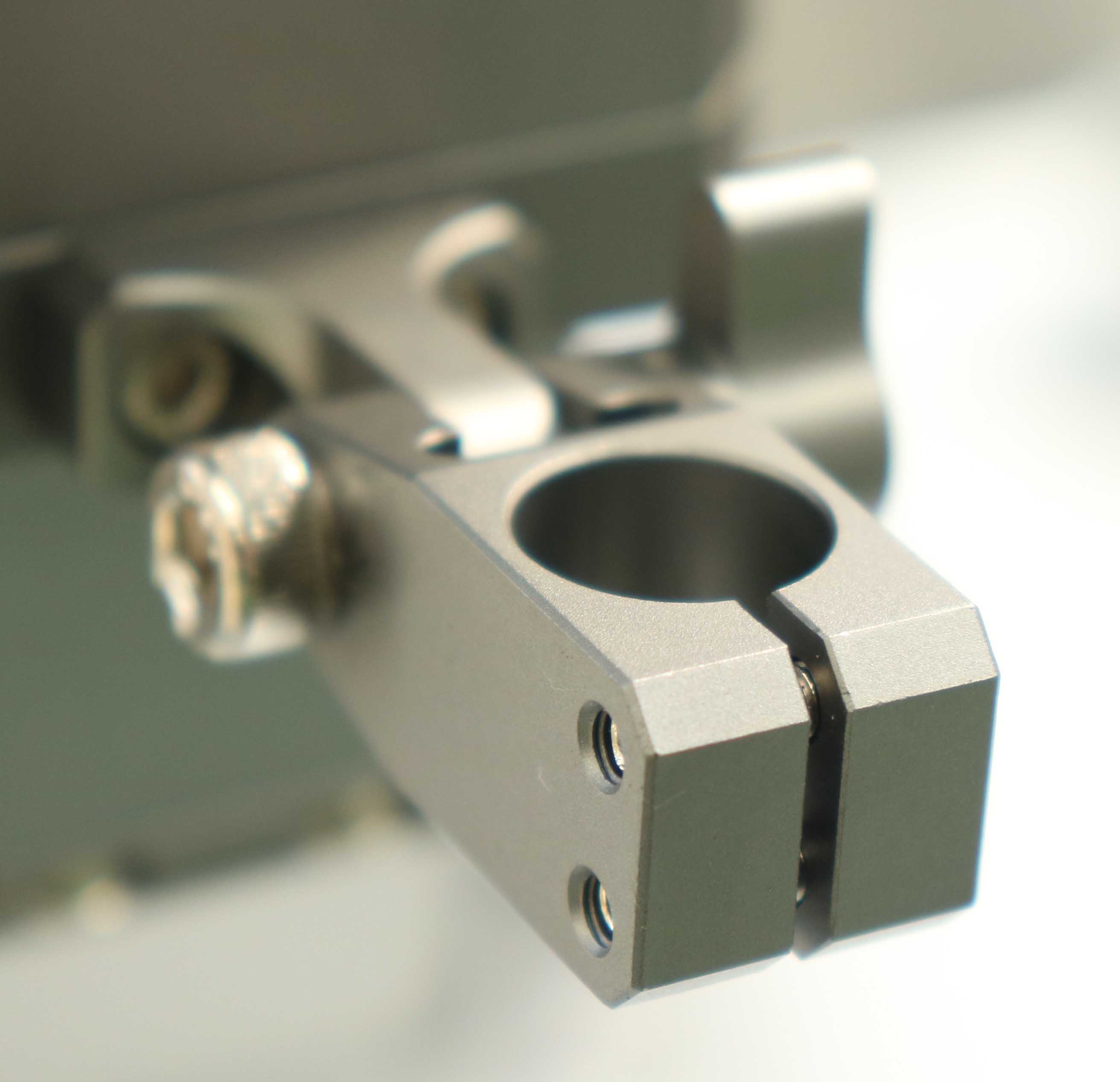

4. Main Parts Details

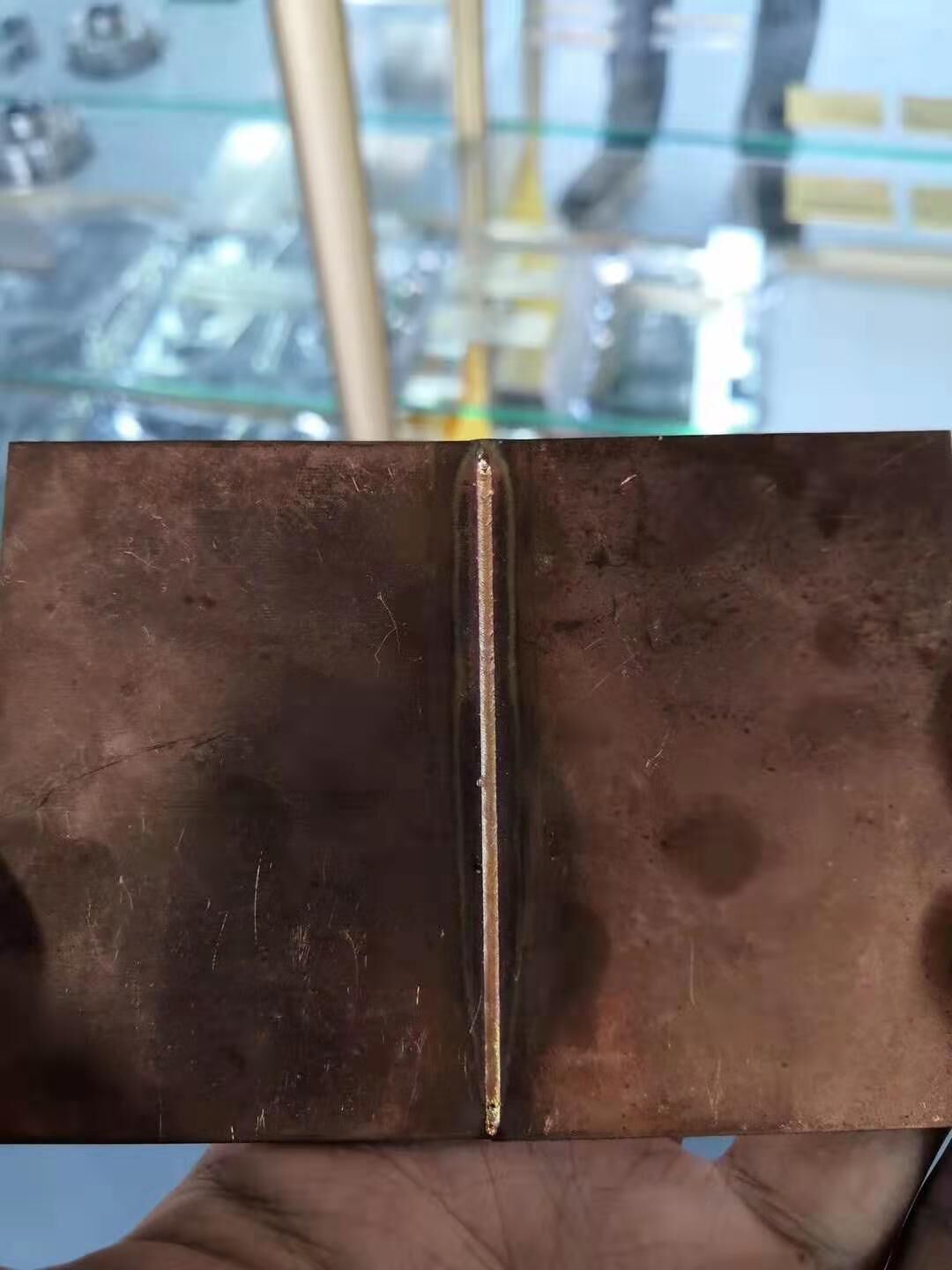

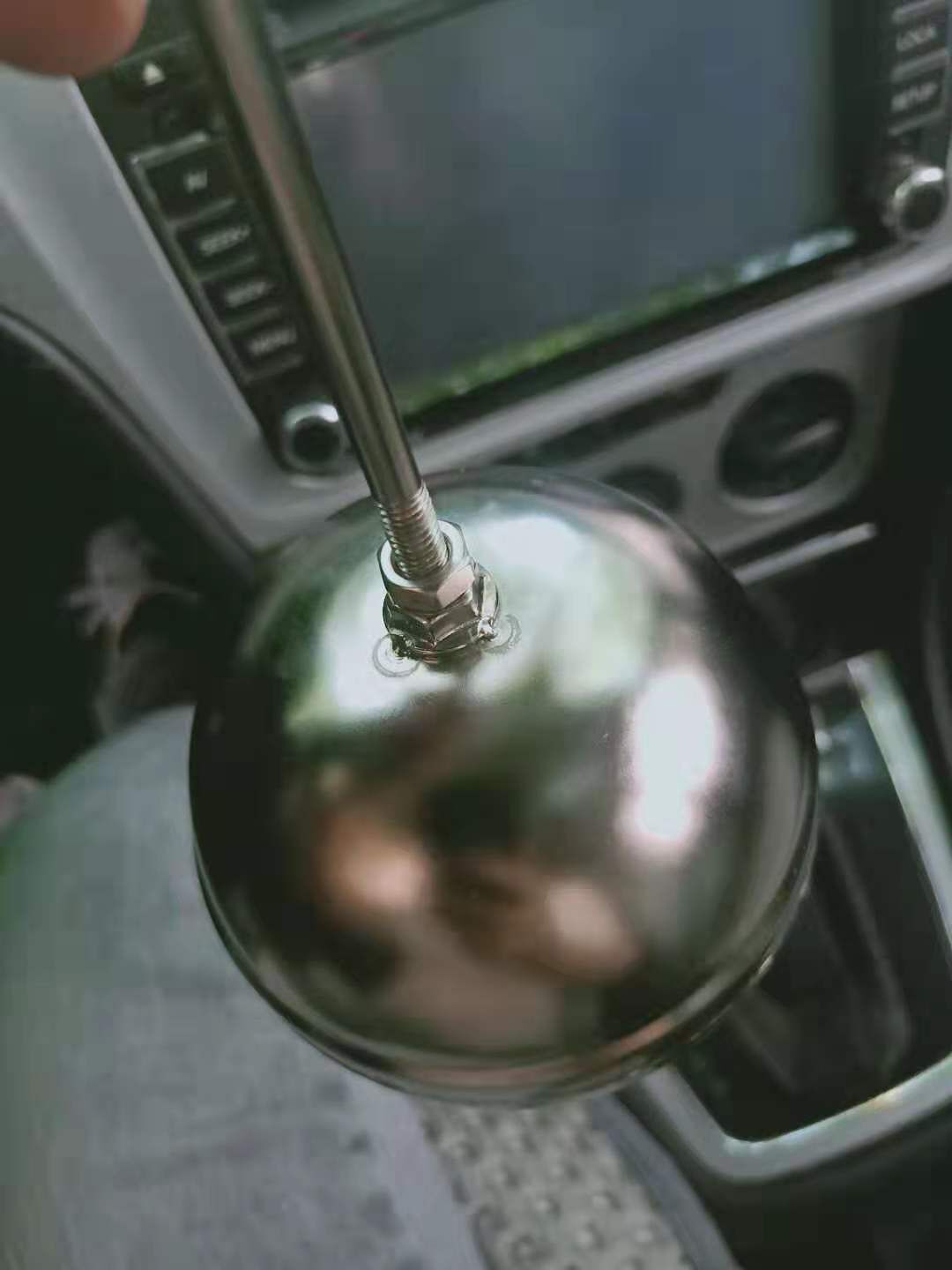

5. Sample Display

.png)

.jpg)

6. Application

Sanitary industry: welding of water pipe

joints, reducers, tees, valves, and showers.

Glasses industry: precision welding of

glasses, such as stainless steel and titanium alloy, and the outer frame.

Hardware industry: impeller, kettle,

handle, etc., welding of insulated cups, complex stamping parts and castings.

Automotive industry: engine cylinder head

gasket, hydraulic tappet seal welding, spark plug welding, filter welding, etc.

Medical industry: welding of medical

instruments, medical equipment, stainless steel seals, structural parts.

Electronics industry: solid-state relay

seal welding, welding of connector connectors, welding of metal casings and

structural parts such as mobile phones and MP3s. Welding of motor housings and

wires, fiber optic connector connectors, etc.

Household hardware, kitchen utensils, stainless steel door handles, electronic components, sensors, watches, precision machinery, communications, handicrafts, and other industries, automotive hydraulic tappets and other high-intensity industry products welding.

7. Package

8. Workshop

9. FAQ

Q1. How about the wavelength adjustment range of the laser welding machine?

1ms~10ms

Q2. What is the power consumption of the welding machine?

Normally, the power of the laser multiplied by 4.5 is the power consumption of the whole laser welding machine.

Q3. Is the protective gas necessary?

Yes, it is. Protective gas must be used to protect and cool the lens and copper nozzle, and to achieve perfect welds;

Q4. How to maintain water chiller?

In the summer, fill the chiller with pure water and replace the water once a month; in the winter, add coolant or alcohol, the volume is half of the water tank; In the extreme cold area, antifreeze should be added;

10.Customer Review

DIHORSE 1k/1.5k/2k/3k Automatic Fiber Laser Welding Machine 300*300mm Working Area with Rotary for Standard Part

- Brand: DIHORSE LLC

- Product Code:DH-W1000

- Availability:In Stock

-

$12,000.00

Available Options

Related Products

DIHORSE 1kw 1.5kw 2kw Handheld Fiber Laser Welding Machine With Auto Feeder System for CS, SS, Aluminum with High Efficiency

1. DescriptionThe Handheld Fiber Laser Welding Machine is a new type high-power, high-end continuous..

$6,900.00